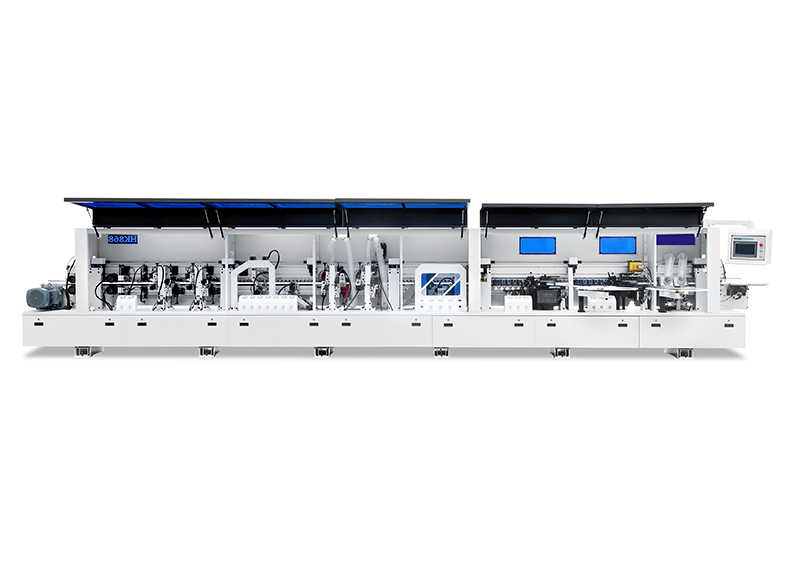

HK868P Ntug Bander tshuab tsis siv neeg

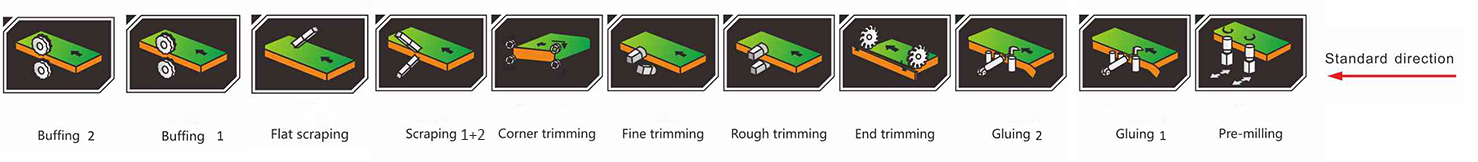

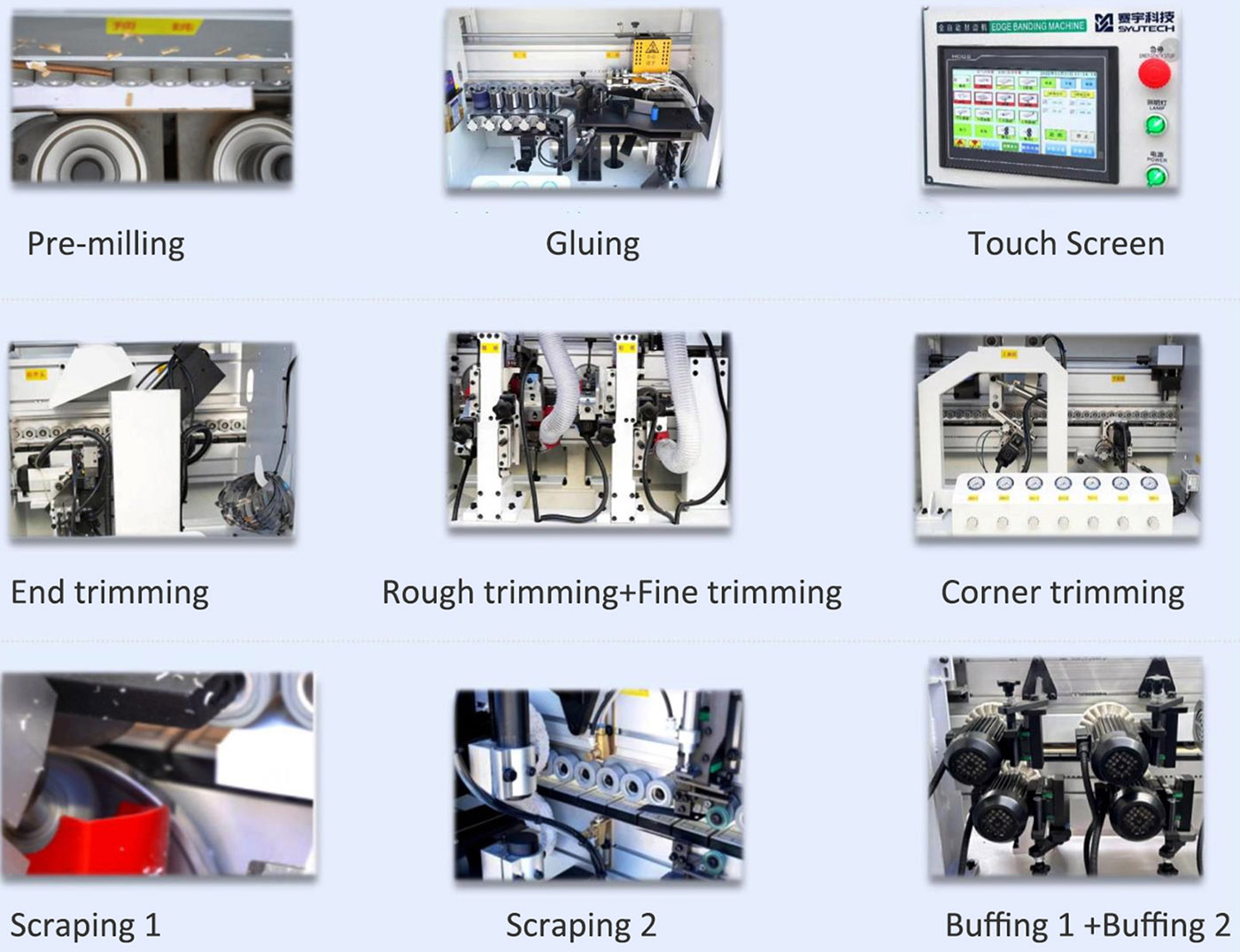

Lub tshuab ntug banding yog ib qho kev xaiv rau kev tuav ntug banding txheej txheem: conveying - gluing thiab welting - txiav - pem hauv ntej thiab nram qab kev sib raug zoo - sab sauv thiab sab trimming - sab sauv thiab sab trimming - sab sauv thiab qis scraping - polishing rau ib tug high degree ntawm automation

Tsis muaj

| Qauv | HK868 |

| Vaj huam sib luag ntev | Min.150mm (pob trimming 45x200MM) |

| Vaj huam sib luag dav | Yam tsawg kawg 40 mm |

| Ntug band dav | 10-60 hli |

| Ntug band thickness | 0.4-3 hli |

| Pub ceev | 18-22-25m / min |

| Nruab lub zog | 21 KW 380V 50HZ |

| Pneumatic zog | 0.7-0.9Mpa |

| Tag nrho qhov ntev | 9500 * 1200 * 1650mm |

Khoom muaj nuj nqi

Tshuab yam ntxwv

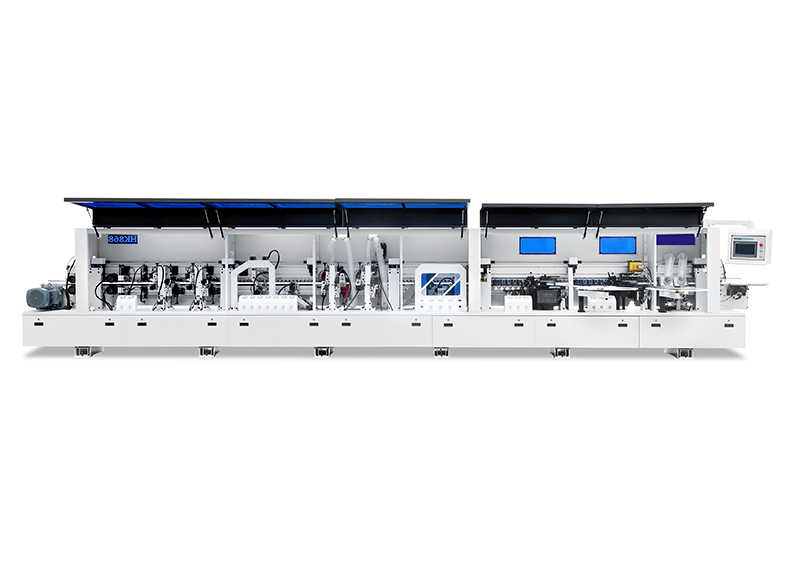

Tag nrho cov khoom hnyav hnyav nrog lub zog zigzag txhawb nqa ko taw

Tag nrho lub tshuab lub cev tau txais kev kho mob annealing

6 kab loj + 11 kab me + 7 lub thawv nqa

Dual motor lifting txhim khu kev ruaj ntseg

Tshuab yam ntxwv

Tag nrho cov khoom hnyav hnyav nrog lub zog zigzag txhawb nqa ko taw

Tag nrho lub tshuab lub cev tau txais kev kho mob annealing

6 kab loj + 11 kab me + 7 lub thawv nqa

Dual motor lifting txhim khu kev ruaj ntseg

Haisen conveying cov menyuam thiab saw thaiv

Muaj zog thiab ruaj khov tsis muaj deformation, nrog lub neej ntev dua

Loj board auxiliary bracket nrog plaub lub strips zoo

Nruab nrog nqaim ntug auxiliary log rau ruaj khov phaj noj

Internet chaw taws teeb tswj system

Yuav tau networked rau kev tswj kub thiab preheating ua ntej

Ntse kov npo nrog lub cim xeeb muaj nuj nqi

Kev txheeb cais ntawm lub sijhawm tiag tiag ntawm kev tsim khoom puv hnub thiab sau cov xwm txheej tsim khoom

Internet chaw taws teeb tswj system

Yuav tau networked rau kev tswj kub thiab preheating ua ntej

Ntse kov npo nrog lub cim xeeb muaj nuj nqi

Kev txheeb cais ntawm lub sijhawm tiag tiag ntawm kev tsim khoom puv hnub thiab sau cov xwm txheej tsim khoom

Lub Circuit Court adopts Suav lus Askiv system

Yooj yim rau kev kuaj xyuas lub zog thiab kev saib xyuas tom qab

Ob txheej ntawm rau lub log xovxwm cov ntawv nplaum, nruab nrog lub log roj hmab thiab scraper hniav, txiav tu thiab tsis nplaum nplaum residue

Ob txheej ntawm rau lub log xovxwm cov ntawv nplaum, nruab nrog lub log roj hmab thiab scraper hniav, txiav tu thiab tsis nplaum nplaum residue

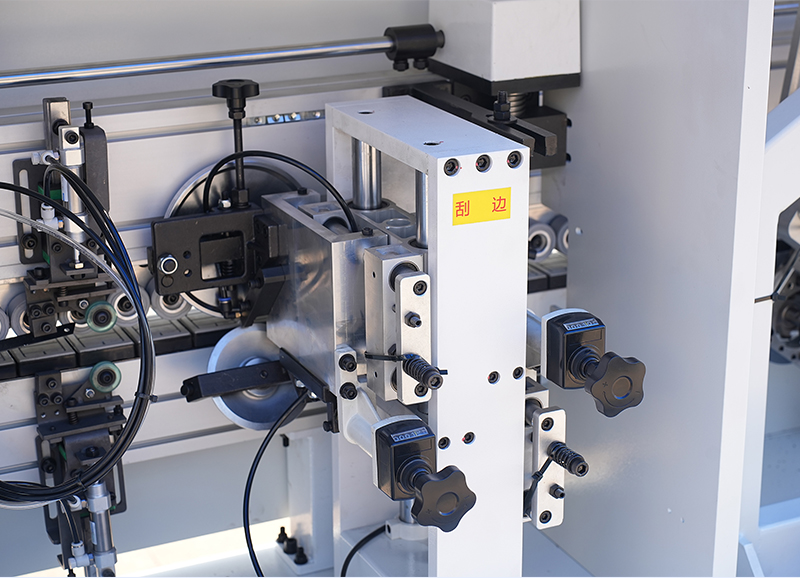

1) Ob txheej ntawm sab sauv thiab sab ntug scraping, txee lub qhov rooj thiab lub cev hom tuaj yeem hloov nrog ib lub pob, tsis tas yuav kho lub tshuab

2) Nrog cov kev taw qhia xaim tshuab kom tiv thaiv cov xaim seem ntawm qhov adhesion thiab tiv thaiv cov npoo tsis ruaj khov los ntawm kev ua rau riam dhia

Heavy Duty Rack

Lub tshuab muaj zog rigidity thiab deformation tsis kam, thiab tom qab vuam, lub thav duab tau dhau los ua ntau yam txheej txheem xws li kev laus, annealing, thiab tsib axis tshuab cuab yeej ua haujlwm kom paub tseeb tias kev ua tiav thiab kev ruaj ntseg mus ntev.

Heavy Duty Rack

Lub tshuab muaj zog rigidity thiab deformation tsis kam, thiab tom qab vuam, lub thav duab tau dhau los ua ntau yam txheej txheem xws li kev laus, annealing, thiab tsib axis tshuab cuab yeej ua haujlwm kom paub tseeb tias kev ua tiav thiab kev ruaj ntseg mus ntev.

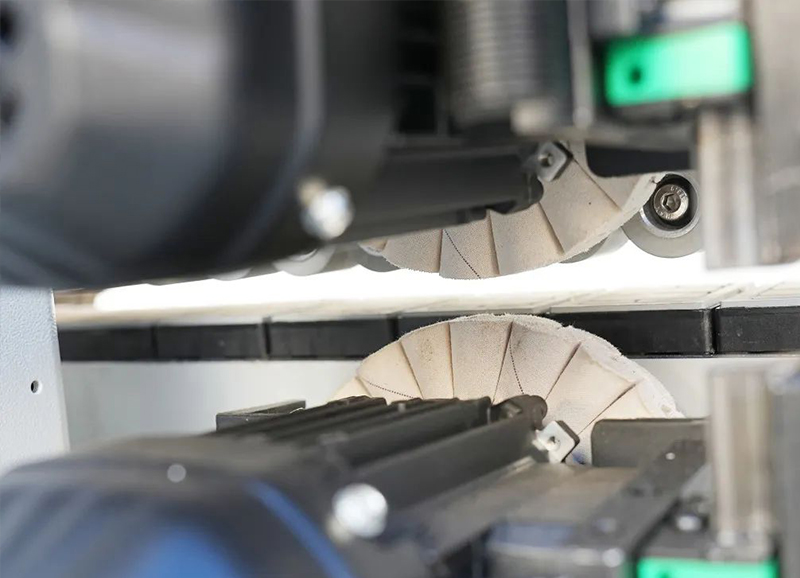

Syutech Patent Yooj Yim Polishing

Muab ob npaug rau polishing, tshem tawm cov plua plav thiab cov nplaum seem, ua kom lub rooj tsavxwm huv si

Cov qauv